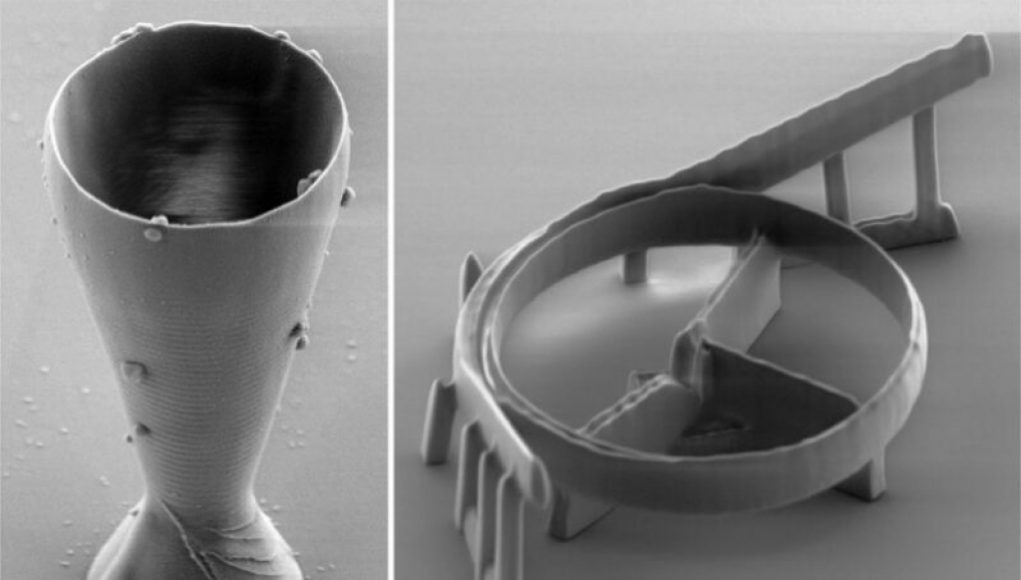

A team of Swedish scientists has revolutionized the 3D-printing of silica glass, simplifying a complex and energy-intensive process. As a remarkable demonstration, they successfully 3D-printed the world’s smallest wineglass, with a rim thinner than a human hair. They also created an optical resonator for fiber optic telecommunications systems, showcasing the vast potential of 3D-printed silica glass components. Their groundbreaking method is detailed in a recent paper published in the prestigious journal Nature Communications.

“The Internet relies on optical fibers made of glass,” explained co-author Kristinn Gylfason from the KTH Royal Institute of Technology in Stockholm. “Our technique allows for the 3D printing of essential filters and couplers used in these systems, opening up countless new possibilities.”

While 3D printing has made significant advancements, printing silica glass, especially at the microscale, has remained a challenge. Previous methods, such as stereolithography and direct ink writing, have only achieved feature sizes in the tens of micrometers range. However, a recent study achieved nanoscale resolution.

These methods typically involve sol-gel processes with organic mixtures containing silica nanoparticles. As a result, the final printed structures are composites with organic materials, lacking the desired properties of pure silica glass, such as thermal and chemical stability, hardness, and optical transparency. To achieve these properties, an additional sintering step at extremely high temperatures is required, limiting the range of potential applications. Additionally, assembling 3D-printed structures into their final form is challenging at the micrometer scale.

Advertisement

The Swedish scientists, led by Gylfason, developed an alternative technique for 3D-printing silica glass using hydrogen silsesquioxane (HSQ). HSQ is an inorganic material similar to silica that can be patterned using electron beams, ion beams, and specific wavelengths of UV light. One major advantage of their method is that it eliminates the need for organic compounds as photoinitiators or binders, which are used in other 3D-printing techniques like stereolithography and direct ink writing. Instead, their method relies on direct cross-linking of the inorganic HSQ.

Their process consists of three main steps. First, they drop-cast HSQ dissolved in organic solvents onto a substrate. Once the HSQ dries, they use a focused sub-picosecond laser beam to trace the desired 3D shape. Finally, any unexposed HSQ is dissolved using a potassium hydroxide solution. Raman spectroscopy confirmed that the printed microstructures exhibited all the expected features of silica glass.

However, there were traces of residual hydrogen and carbon in the printed structures. For applications requiring pure silica glass, the residual organics can be removed by annealing the structures at a lower temperature of 900°C (1,652°F). Although annealing can cause shrinkage or distortion, the maximum shrinkage observed in their silica glass structures was only around 6%, compared to 16% to 56% in glass objects produced using other 3D-printing methods.

In addition to the miniature wineglass and optical resonator, the scientists successfully printed a tiny version of the KTH logo, a cantilever, a conical spiral, and a silica glass optical fiber tip. They believe their method could be used to create customized lenses for medical devices, micro-robots, and more. By coating the 3D-printed microstructures with nanodiamonds or ferrous nanoparticles, they could further tailor the properties for hybrid quantum photonics integration or magnetically controlled motion.

“Different applications have different concerns when it comes to integrating 3D printing methods,” said co-author Po-Han Huang, a graduate student at KTH. “While further optimization is needed for specific applications, we consider our method to be a significant breakthrough for practical 3D glass printing.”

DOI: Nature Communications, 2023. 10.1038/s41467-023-38996-3 (About DOIs).

On November 12, 2020, a team of scientists from the Chalmers University of Technology in Sweden made a major breakthrough by creating the world’s smallest 3D-printed wineglass. The scientists used a new type of 3D printing method that allowed them to create the wineglass in tiny dimensions of just 8.5 millimeters high, with a diameter of 7 millimeters.

The research team, led by doctoral student Hao-Ching Chiang, was also able to accurately control the shape and size of the wineglass with extreme precision. Utilizing the 3D-printing process, the scientists were able to produce the wineglass with a wall thickness that was just 0.4 millimeters.

In order to create this miniature wineglass, the scientists had to make use of a new type of 3D-printing technology called “Atom Printing.” This revolutionary technique enables objects to be printed with extremely small details and microstructures.

The research team also took the materials used to produce the wineglass into consideration. The wineglass was printed in a stainless-steel alloy called “Maraging Steel.” This type of steel offers excellent corrosion resistance and strength in such a small form.

In a statement to the press, Hao-Ching Chiang said, “We have created a very detailed miniature wineglass. This size opens up whole new possibilities for 3D-printed objects — and not just for the food and beverage industry.”

This new technology has the potential to create objects in similar miniature sizes for a variety of other applications. It could be used to create new products for the medical and pharmaceutical industries, jewelry, electronics and more.

Although there is still a long way to go for Atom Printing to be fully developed and accepted as a commercial technology, this latest achievement shows that 3D printing technology is evolving rapidly. This new step forward in 3D printing presents a unique opportunity for the production of tiny objects with accuracy and precision.