Exciting news from Varda Space Industries! Their first space mission is nearing its end with a groundbreaking re-entry and landing in Utah. The California-based startup has successfully grown crystals of the drug ritonavir in orbit using a miniature lab.

The journey began on June 12 when Varda’s spacecraft was launched as part of a rideshare mission on a SpaceX Falcon 9 rocket. After several weeks of checkouts, the mini-lab embarked on a 27-hour drug-manufacturing experiment. Ground controllers gave the go-ahead, and the lab started growing ritonavir crystals, a drug commonly used to treat HIV.

The experiment concluded on June 30, and data downlinked from the spacecraft confirmed its success. This achievement marks the first time that orbital drug processing has occurred outside of a government-run space station.

Delian Asparouhov, Varda’s co-founder, expressed his excitement on Twitter, stating, “Space drugs have finished cooking baby!” Asparouhov, along with co-founders Will Bruey and Daniel Marshall, established Varda in 2020. They are thrilled with the progress of their demonstration mission.

Asparouhov explained, “One of the critical parts of pharmaceutical processing is being able to maintain appropriate temperature ranges for extended periods of time. It was exactly per our expectations, which is really great to see.”

Varda has big plans for the future, including a sequence of satellite missions. The current spacecraft in orbit is the first of Varda’s Winnebago series, designed to bring pharmaceutical research specimens back to Earth for analysis and commercial use.

Advertisement

The satellite, weighing approximately 660 pounds (300 kilograms), was built in partnership with Rocket Lab. Rocket Lab provided a solar-powered carrier module, or bus, which supplied electricity, communications, propulsion, and attitude control. Varda added a nearly 3-foot-diameter (1-meter) re-entry capsule to Rocket Lab’s satellite platform.

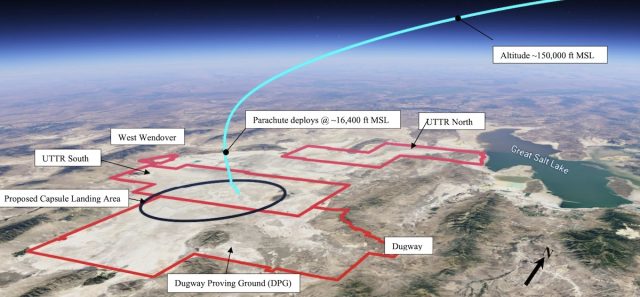

In the next few weeks, Rocket Lab’s ground team will initiate a braking maneuver to drop the satellite out of orbit. This will set it on a course to re-enter the atmosphere and land at the US military’s Utah Test and Training Range. The re-entry capsule, weighing nearly 200 pounds, will separate from the carrier craft before re-entry. NASA-developed heat shield material will protect the capsule from extreme temperatures as it descends through the atmosphere. If all goes according to plan, a main parachute will deploy to ensure a gentle landing.

FAA license pending

Varda is currently collaborating with Rocket Lab, the Federal Aviation Administration, and the military to schedule the mission’s return to Earth. While the landing window opens on July 17, the actual return date is likely to be later this month. Asparouhov stated, “Now, we’re more in the phase of getting everything lined up between the satellite performing the deorbit burn, as well as the regulatory partners helping with airspace control, all the way down to the military resources that will be helping us with the actual retrieval on the range.”

In early June, Varda and its partners conducted a rehearsal for the recovery in Utah, just a week before the mission’s launch.

In an exciting breakthrough for in-space manufacturing technology, a startup has successfully conducted a pharmaceutical experiment in orbit.

The company, Space Pharmacy, based in Florida, is a leading firm pioneering new technology that allows for the production of drugs and pharmaceuticals in the harsh conditions of space. The company recently completed a major experiment aboard the International Space Station (ISS).

Space Pharmacy has developed a unique approach to drug production and assembly in space. The process involves combining specific molecules in a reaction to synthesize custom-made drugs on demand. The understanding that unique conditions and radiation exposure can transform the effectiveness of drug molecules is what has driven the company’s success so far.

The team tested out their new Space Pharmacy device on board the ISS. Their aim was to prove their in-space pharmaceutical manufacturing system could withstand long-term use in the challenging conditions of outer space.

The experiment ran smoothly, and the team was able to successfully produce a particular medication. According to Space Pharmacy, the drug reacted differently in weightlessness than what would occur on Earth’s surface, proving that the device could produce medications with greater efficacy in outer space.

Space Pharmacy’s experiment is seen as a major step forward towards the normalization of cost-effective, on-demand drug production in space. Currently, the manufacturing and delivery of drugs and pharmaceuticals is a lengthy and complex process with many limitations. The company is hoping their successful experiment will encourage further investment into in-space manufacturing technology and lead to greater advancements in space exploration.

The company’s CEO stated that this successful experiment has led to an “unprecedented level of excitement” for Space Pharmacy’s future developments. As the pioneering innovator in this area of research, it looks set to be a record-breaking year for the firm. The possibilities for in-space manufacturing, especially in the pharmaceutical field, are truly transforming the space industry as we know it.