SpaceX’s recent Falcon 9 rocket launch to the International Space Station included new scientific gear that could play a crucial role in the development of materials for future human space flights. Among the new equipment are four tablets covered with extremely thin films developed by the French commission for atomic and renewable energy (CEA). Testing these innovative films is part of an ongoing project aimed at developing antibacterial materials for space habitats. The project, called MATISS (Microbial Aerosol Tethering on Innovative Surfaces in the International Space Station), involves exposing the tablets to the ISS environment for a long time to collect bacteria that gets deposited on them. The tablets are then returned to laboratories for measuring the level of biocontamination. With the ISS being 400 km above the Earth in a near-vacuum, one might expect it to have a sterile environment. However, thanks to the constant presence of astronauts, the ISS is teeming with bacteria and fungi. The MATISS project was launched in 2016, and the first set of experiments served as proof of concept. For the upcoming mission, glass tablets covered with antibacterial surfaces have been placed in four holders, each measuring 8×8×1.5 cm. Each holder has six windows where the smart surfaces get exposed to the ISS environment. The goal is to build active surfaces that would not only protect astronauts but also help them reduce the time needed for cleaning the surfaces.

On the International Space Station (ISS), scientists are testing a new kind of antibacterial surface designed to help astronauts stay healthy. This novel surface, created by a team of aerospace engineers at Georgia Tech, works by combining a nanofiber mesh and an antifungal compound which is then coated onto aircraft materials.

The team tested the surface in extreme environment simulations replicate the changes in temperature, atmospheric pressure, radiation and other conditions experienced on the ISS. The results from these tests showed the surface was resistant to both fungal and bacterial growth in extreme conditions.

These tests were conducted to not only ensure the safety of astronauts by protecting them from pathogen exposure, but to also research how these harmless antioxidants can help prevent undesirable biofilm-buildups in confined spaces. The surface was also found to give off an antibacterial effect for up to three weeks without having to be replaced.

The surface could also provide the ISS’s maintenance crew with the ability to replace costly antibacterial coatings with this antibacterial surface, allowing for easier and more cost-effective disinfecting and cleaning. This was also found to be attractive for industries such as healthcare, where these surfaces can help reduce the risk of infections in medical facilities.

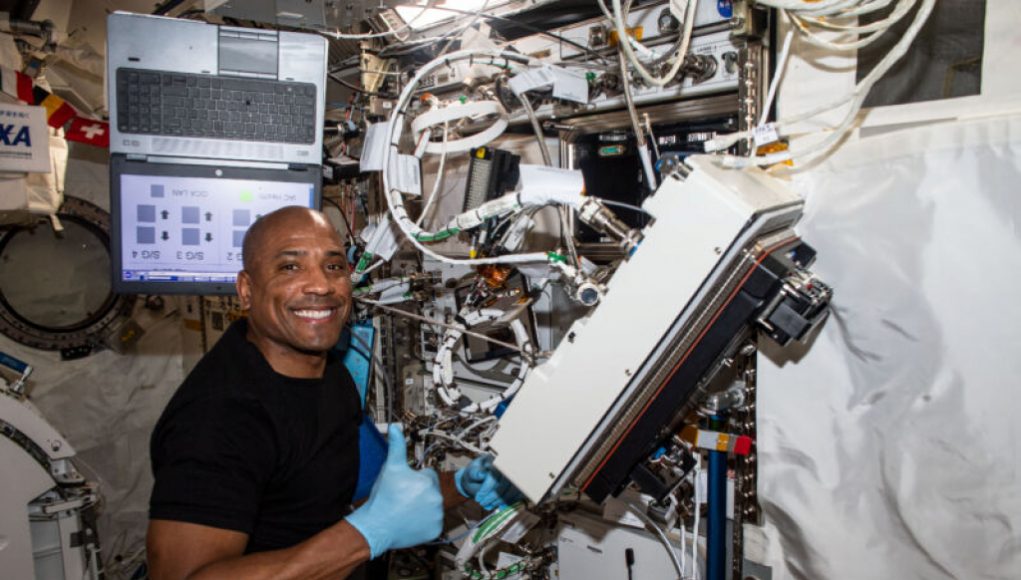

This new antibacterial surface has been sent to the ISS where a new series of experiments are being conducted by astronauts. If the results from these tests are promising, the surface could become commonplace on the ISS, providing astronauts with better protections against microbial infections and bio-contamination.